2D Laser Cutting in Oxfordshire and Across the UK

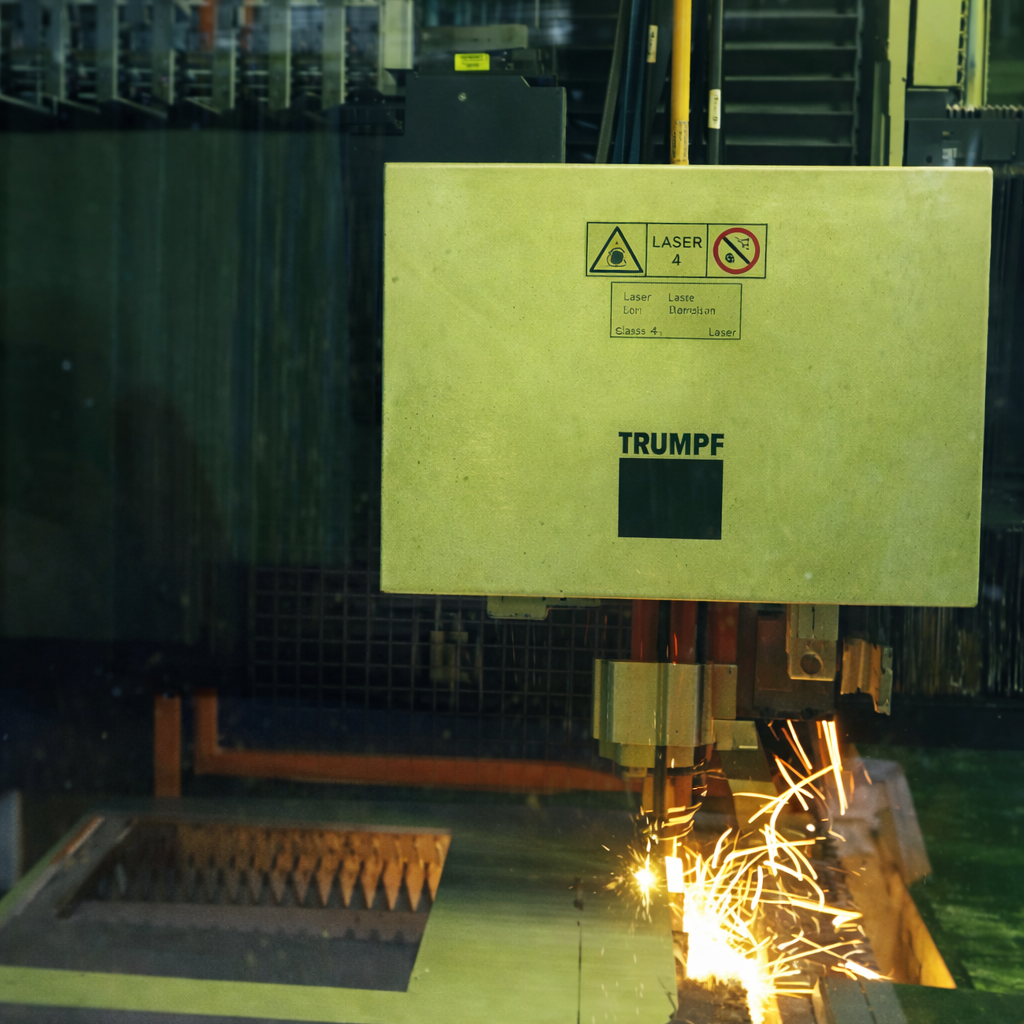

At LTi Metaltech, our 2D laser cutting services deliver fast, precise, and repeatable results for a wide range of metallic components. Using state-of-the-art CNC laser cutting system, we achieve clean edges, tight tolerances, and consistent quality - supporting both prototype development and high-volume production.

Operating from our advanced manufacturing facility in Oxfordshire, we provide laser cutting services to customers across the UK in healthcare, energy, nuclear and fusion, and renewable industries, where precision and reliability are essential.

High-Speed, High-Accuracy Metal Cutting

Our 2D laser cutting process uses a highly focused laser beam to cut metals with exceptional speed and accuracy. This non-contact, thermally efficient method minimises distortion, reduces waste, and produces clean edges, ideal for intricate geometries and detailed component profiles.

With a large 4-metre by 2-metre cutting bed, we can accommodate oversized sheet materials while maintaining consistent, high-quality results. We can process:

-

Stainless steel / Nickel alloy: up to 35 mm

-

Aluminium: up to 25 mm

-

Copper / Brass: up to 12 mm

These capabilities make LTi Metaltech a strong partner for fabricators and OEMs needing high-integrity components across a wide range of metals and thicknesses.

Capabilities and Benefits

Our 2D laser cutting delivers fast, reliable cutting for thin to medium-gauge metallic materials with exceptional accuracy and repeatability - ideal for precision components and high-volume production. Clean, burr-free edges minimise post-processing while tight tolerances maintain dimensional accuracy across large production runs. With a large-format 4m × 2m bed, we can accommodate oversized parts and assemblies, all while maximising material utilisation through efficient nesting and CNC programming. Whether producing one-off prototypes or full-scale manufacturing batches, our process ensures consistent quality, cost-effective performance, and scalable production.

Typical Applications

- Precision blanks, panels, and flanges

- Structural and enclosure components for energy and industrial systems

- Stainless steel and aluminium assemblies for healthcare and scientific equipment

- Intricate profiles for complex welded or machined assemblies

Why Choose LTI Metaltech?

- Proven expertise in precision metal cutting and fabrication

- Advanced CNC-controlled laser technology for accuracy and repeatability

- ISO-certified quality assurance and rigorous inspection at every stage

- Trusted supplier to nuclear, fusion, energy, and healthcare sectors

- Reliable project delivery with short lead times and consistent results