CNC Edge Preparation

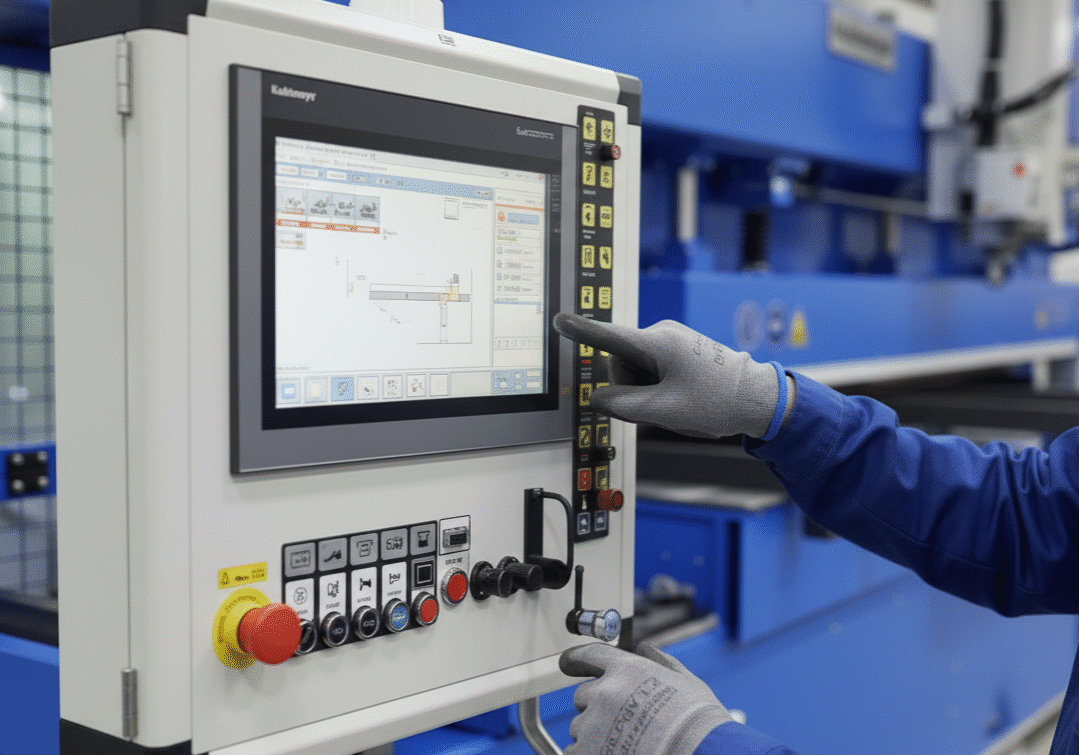

At LTi Metaltech, our CNC edge preparation services deliver precise, consistent, and contamination-free edge finishes for stainless steel components. Using advanced CNC-controlled deburring and chamfering systems, we achieve perfectly angled or profiled edges - ensuring superior weld quality, component fit, and enhanced structural performance, all tailored to exact customer specifications.

Based in Oxfordshire, we support clients across the nuclear, fusion, energy, healthcare, and renewable sectors, where weld integrity and repeatable precision are critical to safety and reliability.

Precision Finishing for High-Integrity Fabrication

Edge preparation plays a vital role in ensuring the quality and long-term performance of stainless steel fabrications. Our automated system performs deburring and edge profiling with exceptional accuracy, producing consistent geometries and smooth transitions that are immediately ready for welding or assembly.

By replacing manual preparation with CNC automation, we deliver repeatable results, maintain precise bevel angles, and significantly reduce production time - supporting efficient, high-integrity manufacturing.

Capabilities & Benefits

Our automated, CNC-controlled edge preparation system delivers consistent, repeatable results across a wide range of weld geometries. Precision deburring, beveling, chamfering, and surface conditioning ensure clean, accurately prepared edges that support stronger weld joints, improved penetration, and long-term structural integrity. The process also removes sharp edges, oxides, and contaminants, making it ideal for stainless steel components used in critical fabrication projects.

We can produce a variety of edge profiles and angles, including multi-angle bevels, tailored to specific weld designs and complex assembly requirements.

Key Benefits:

-

Consistent, controlled edge geometry for enhanced weld quality

-

Improved component fit-up with reduced rework during fabrication

-

Cleaner surfaces that support superior weld penetration and minimise contamination risks

-

Reduced reliance on manual processes - boosting efficiency and repeatability

-

Faster preparation times aligned with lean manufacturing and shorter project turnaround

Typical Applications

Our CNC edge preparation services are trusted for projects where precision welding, structural integrity, and dimensional accuracy are essential, including:

- Pressure vessels and containment systems

- Structural fabrications for nuclear and energy sectors

- High-integrity stainless steel assemblies for healthcare and scientific equipment

- Precision components requiring controlled weld geometry

Why Choose LTI Metaltech?

- Proven expertise in high-integrity fabrication and precision engineering

- Advanced CNC-controlled edge preparation technology

- ISO-certified quality assurance ensuring full traceability and consistency

- Experienced engineers with decades of specialist knowledge

- Trusted supplier to the nuclear, fusion, energy, and healthcare sectors

Edge Preparation for Aluminium

While our CNC edge preparation systems are primarily designed for stainless steel, we also offer edge preparation for aluminium using specialist alternative methods to ensure the same high-quality finish and weld readiness.