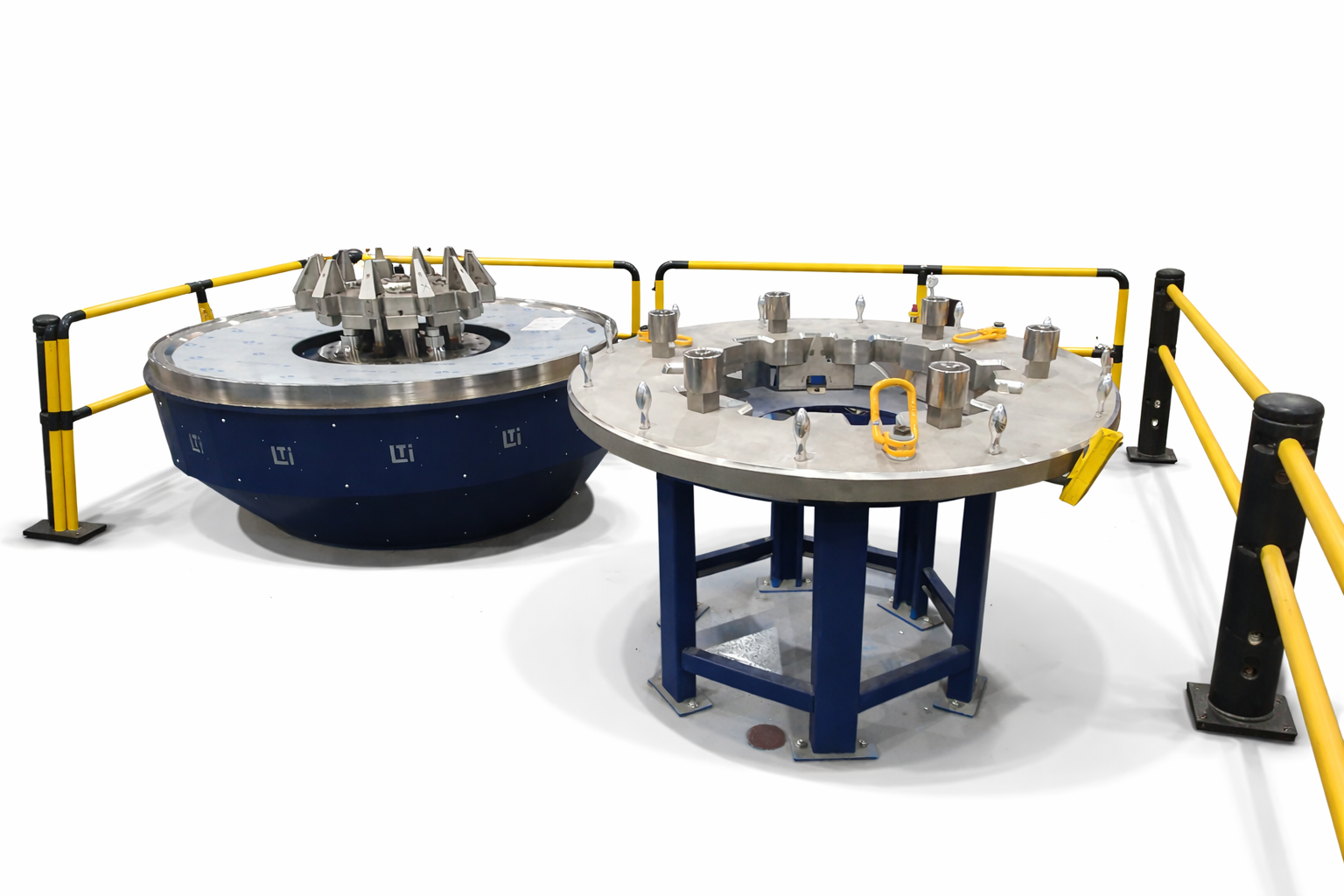

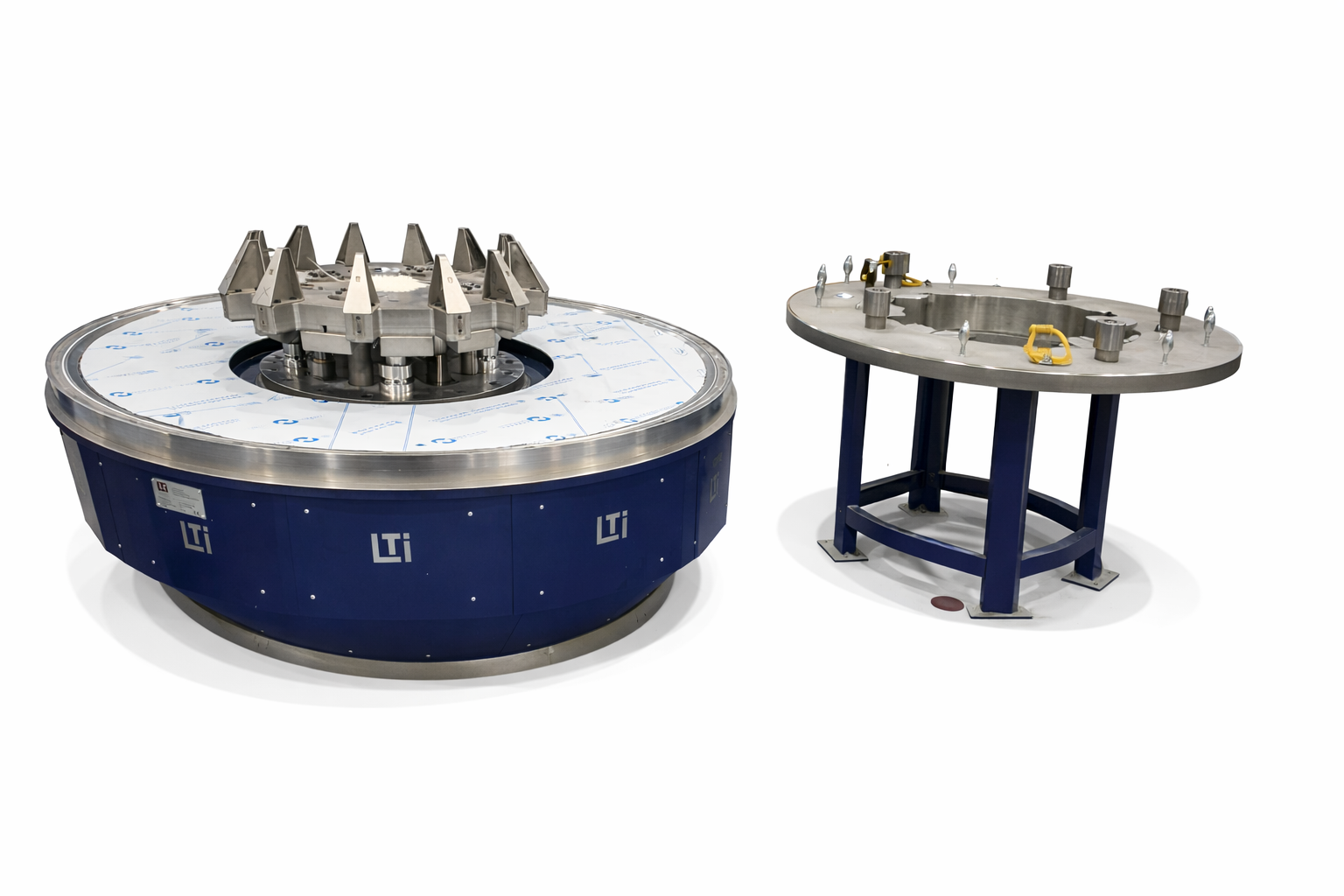

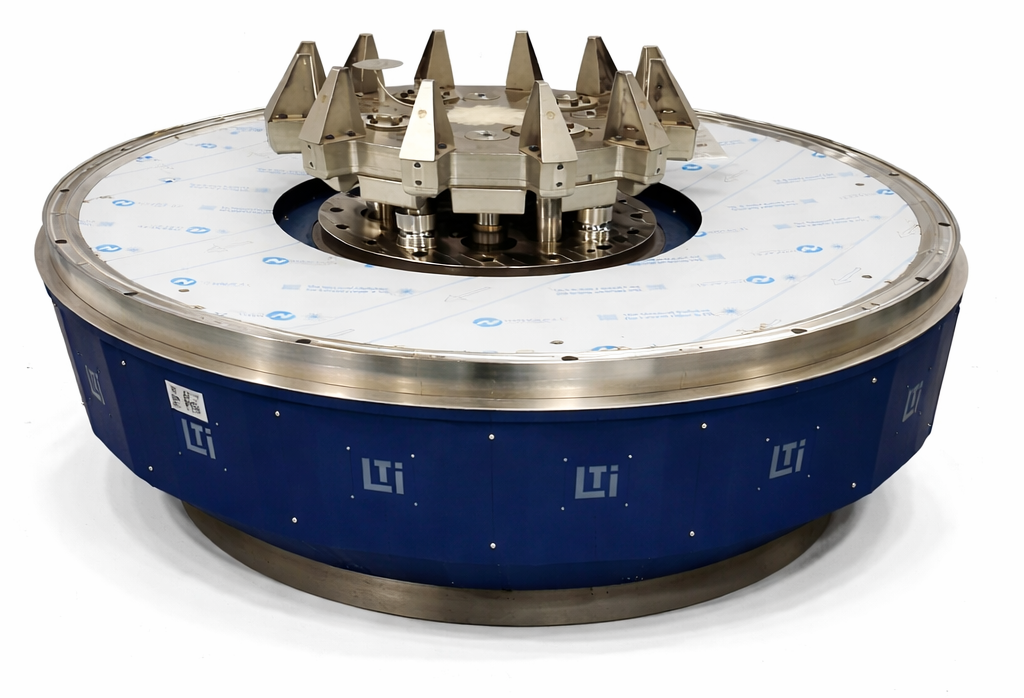

Bespoke Forming – Conical End Press

At LTi Metaltech, our bespoke forming services include the use of a conical end press for producing precision-formed conical ends, tailored to the unique requirements of high-integrity vessels and assemblies. This advanced forming capability allows us to manufacture custom geometries, complex contours, and non-standard profiles with exceptional accuracy, consistency, and surface integrity.

Operating from our state-of-the-art facility in Oxfordshire, we deliver bespoke formed components to clients across the nuclear, fusion, energy, healthcare, and renewable sectors - where precision forming, repeatability, and material integrity are critical to performance.

Precision Forming for Custom Vessel Ends

Our conical end press enables the precise shaping of stainless steel and aluminium plate into conical ends. This method provides controlled forming pressure across the entire surface area, ensuring smooth transitions, uniform thickness, and repeatable geometry - essential for pressure-rated and safety-critical components.

Whether forming a single prototype or repeat production batch, our skilled technicians and engineers work closely with clients to ensure that every bespoke component meets exact dimensional and material requirements.

Applications

- Pressure vessel ends

- Stainless steel and aluminium end caps

- Specialised geometries for fusion, energy, or cryogenic systems

Capabilities

- Conical end forming using bespoke press tooling

- Suitable for stainless steel and aluminium in various grades and thicknesses

- Controlled forming pressure ensures dimensional consistency and surface quality

- Custom tooling and die design for unique profiles or non-standard diameters

Benefits of Conical End Press Forming

- High dimensional accuracy and repeatable geometry

- Uniform wall thickness and smooth surface transitions

- Reduced residual stress through controlled cold-forming pressure

- Enhanced weld preparation and assembly compatibility

- Fully bespoke designs to suit specific vessel or system configurations

Why Choose LTI Metaltech?

- Proven expertise in precision forming and bespoke fabrication

- Advanced conical end press equipment for complex geometries

- CNC-assisted control ensuring accuracy and repeatability

- ISO-certified quality systems and full process traceability

- Trusted partner to nuclear, fusion, energy, and healthcare sectors