Precision Fabrication for Critical Energy Applications

Trusted by world leaders in fusion, renewables, and energy innovation

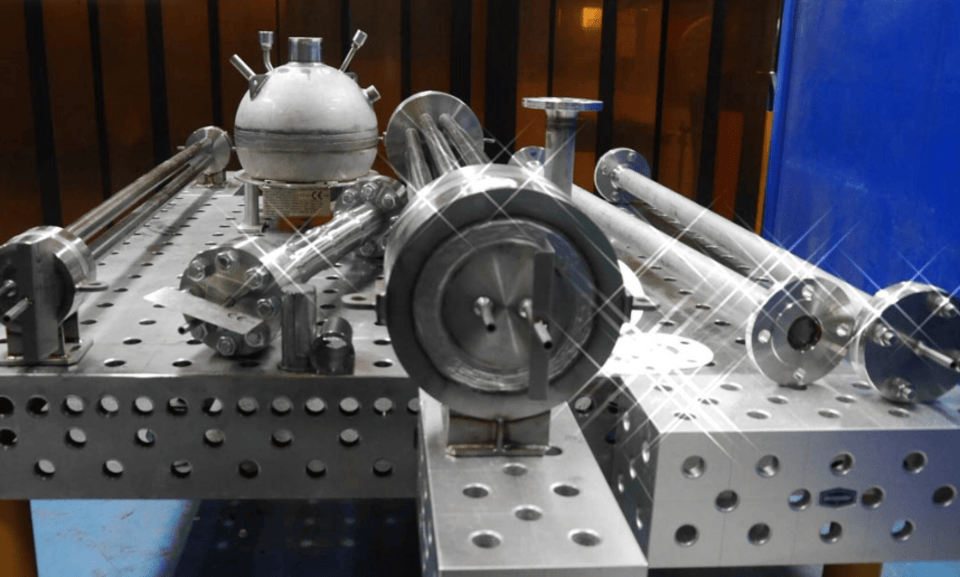

For over two decades, LTi Metaltech has delivered high-end fabrication and welding services for some of the most complex and safety-critical energy projects in the UK and beyond. Trusted by global leaders such as Tokamak Energy, CERN, STFC, and Siemens CT, we provide the precision, reliability, and compliance required for technologies that push the boundaries of science and power the transition to clean energy.

From next-generation nuclear fusion systems to pressure-rated vessel structures for offshore renewables, our work enables the breakthroughs that will define the future of energy.

Engineering Confidence into Every Component

Energy sector projects demand absolute control over materials, tolerances, and environmental integrity. Whether supporting nuclear fusion development or fabricating pressure vessels for offshore use, the stakes are high - and so is the scrutiny. Our team brings deep knowledge of material science, advanced welding procedures, and rigorous quality assurance to every project.

Each fabrication is more than a part – it’s a critical link in a high-performance system where safety, compliance, and reliability cannot be compromised.. That’s why industry leaders trust us to deliver with repeatable precision and verified compliance.

Our Technical Capabilities

Our fabrication systems are built to meet the challenges of energy innovation. Key capabilities include:

• Materials Expertise: Extensive experience with stainless steels, exotic alloys, and vacuum-compatible materials used in high-energy and clean environments.

• Advanced Welding: TIG, MIG, Plasma ARC, and specialised techniques for high-integrity joints and pressure vessel compliance.

• Full Traceability: Batch and process documentation aligned to sector standards, supporting robust QA audits and long-term project validation.

• Integrity Testing & Compliance: Hydrostatic testing, dye penetrant inspection (DPI), vacuum testing, and weld qualification to meet sector-specific regulatory demands.

• Complex Geometry Handling: Bespoke fixturing, tooling, and fine-tolerance assembly of intricate structures.

Powering the Future Together

At LTi Metaltech, our ethos is simple: “Making Stuff That Matters.” In the energy sector, that means engineering the components that make fusion power possible, strengthen renewable energy systems, and support scientific discovery.

📩 Get in touch - partner with us to engineer the energy technologies that will power tomorrow’s world.