Siemens CT Energy Storage

LTi Metaltech was selected to manufacture key components for a UK Government-funded green ammonia energy project, led by Siemens CT. The initiative focused on ammonia synthesis, a process that converts hydrogen and nitrogen into ammonia using a catalyst under extremely high temperatures and pressures.

Ammonia is increasingly recognised as a critical enabler in tackling two of the 21st century’s biggest challenges: ensuring future food security (as a fertiliser) and providing a carbon-free fuel source for sustainable energy.

The Challenge

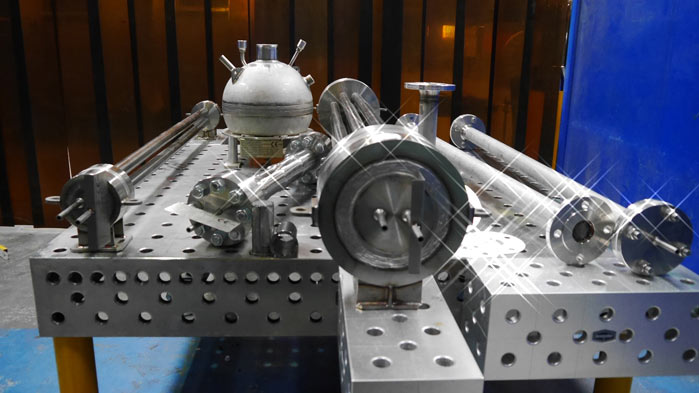

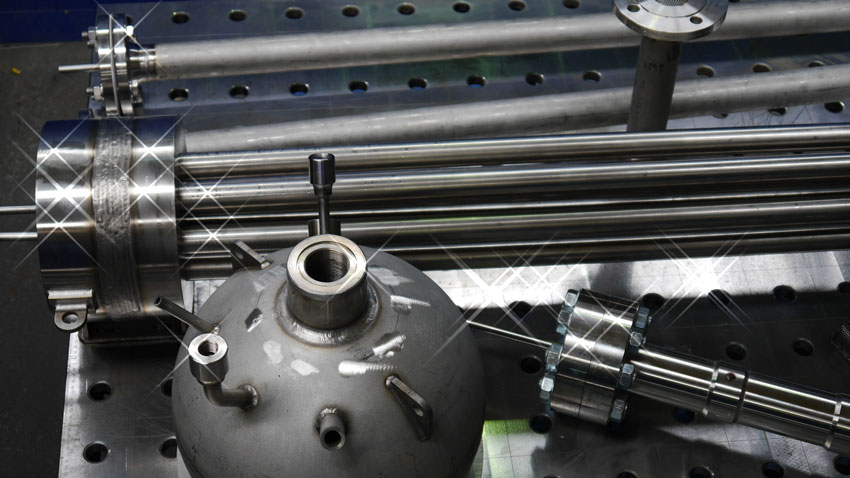

LTi was tasked with manufacturing a wide range of high-integrity pressure vessels and fabricated components for Siemens CT’s government-funded green ammonia project. These included two receiver vessels, two heat exchangers, two vessel dryers, a synthesis vessel, a de-oxidisation vessel, and a condenser tube array.

The complexity of the original designs posed several significant challenges. Their geometric configurations made it extremely difficult to conduct the necessary regulatory testing in their existing form. At the same time, the vessels needed to withstand immense internal pressures of more than 500 bar while operating at elevated temperatures - conditions that left no margin for error in terms of material integrity or weld quality.

Another challenge came from the materials specified in the original brief, which incorporated unusually high safety factors well beyond industry norms. While this ensured strength, it also made the designs heavier and more expensive to manufacture. For LTi, the critical task was to identify ways of optimising the design and material thickness in order to reduce manufacturing costs, while still delivering components that were fully compliant, fit for purpose, and capable of operating under such extreme conditions.

How LTi went about it

Working to EN 13445 European Pressure Vessel Standards, which define the minimum requirements for the design, fabrication, and inspection of vessels, LTi Metaltech applied its expertise to re-engineer Siemens CT’s original specifications into a compliant, efficient, and cost-effective solution.

One of the first steps was to advise Siemens on adopting a spherical vessel design in place of the original square-based concept. This geometry significantly reduced potential weak points and eliminated likely points of failure, ensuring greater long-term integrity.

LTi also drew on its extensive experience in the manufacture of pressure and vacuum vessels to conduct a detailed investigation into how applied stresses could affect both the material and the overall design. These reviews confirmed that the required safety factors could be achieved even with thinner materials, enabling the fabrication of vessels that were lighter, more cost-effective, and still fully fit for purpose.

Ensuring regulatory compliance was another critical element. The components required 100% ultrasonic non-destructive testing (NDT) to detect hidden flaws such as cracks within the metal structure. However, the complex geometries of the original design made testing challenging. To overcome this, LTi worked in close collaboration with the British Standards Institute (BSI), carrying out intermediate testing during manufacture to demonstrate that sound engineering practices were being followed throughout. This rigorous process ultimately ensured that every component met the highest compliance standards.

Finally, LTi optimised the welding process itself. By choosing MIG (metal inert gas) welding over the more traditional TIG (tungsten inert gas) welding, the team was able to accelerate production while maintaining weld integrity. MIG’s use of a continuously fed metal electrode wire allowed for faster bonding and reduced overall welding times, making it a critical factor in improving manufacturing efficiency without compromising quality.

What was the outcome?

Through a combination of design innovation, material optimisation, and advanced welding techniques, LTi Metaltech successfully delivered pressure vessel components that were:

-

Lighter and more cost-effective, reducing material use without compromising safety.

-

Fully compliant with EN 13445 standards, validated through rigorous NDT and BSI oversight.

-

Manufactured more efficiently, with faster lead times thanks to optimised welding processes.

-

Stronger and more resilient, capable of withstanding pressures of more than 500 bar at elevated temperatures.

By supporting Siemens CT’s green ammonia energy project, LTi played a key role in advancing the development of sustainable, carbon-free energy storage technologies - a solution with the potential to transform both food production and global energy systems.